Subway tunnel fires have historically posed a significant threat to passenger safety, resulting in numerous fatalities and catastrophic consequences worldwide. According to available data, between 1987 and 2003 alone, over 500 people lost their lives in subway tunnel fires across the globe. In New York City, there were 1,006 subway fires on tracks, in stations and on trains in 2021. These alarming statistics prompted national and international authorities to intensify their efforts in optimizing emergency evacuations and enhancing smoke control strategies.

In response to this critical challenge, the AENEAS experiment emerged as a groundbreaking initiative that aimed to revolutionize smoke control in subway tunnels. By harnessing the power of HPC-based engineering design and advanced CFD simulations, ENGYS, in collaboration with TECNOSISTEM and CINECA, developed an innovative solution that not only enhances safety measures but also transforms the way we approach emergency preparedness in underground mass transport.

Traditional methods used by engineering companies relied on trial-and-error approaches and approximate techniques, often resulting in suboptimal designs and compromised passenger safety. The AENEAS experiment sought to change this by introducing a novel approach that leveraged detailed 3D simulations and time-varying ventilation control, unlike the iterative and approximate methods that were predominantly employed in the past.

The Solution: A Revolutionary Approach

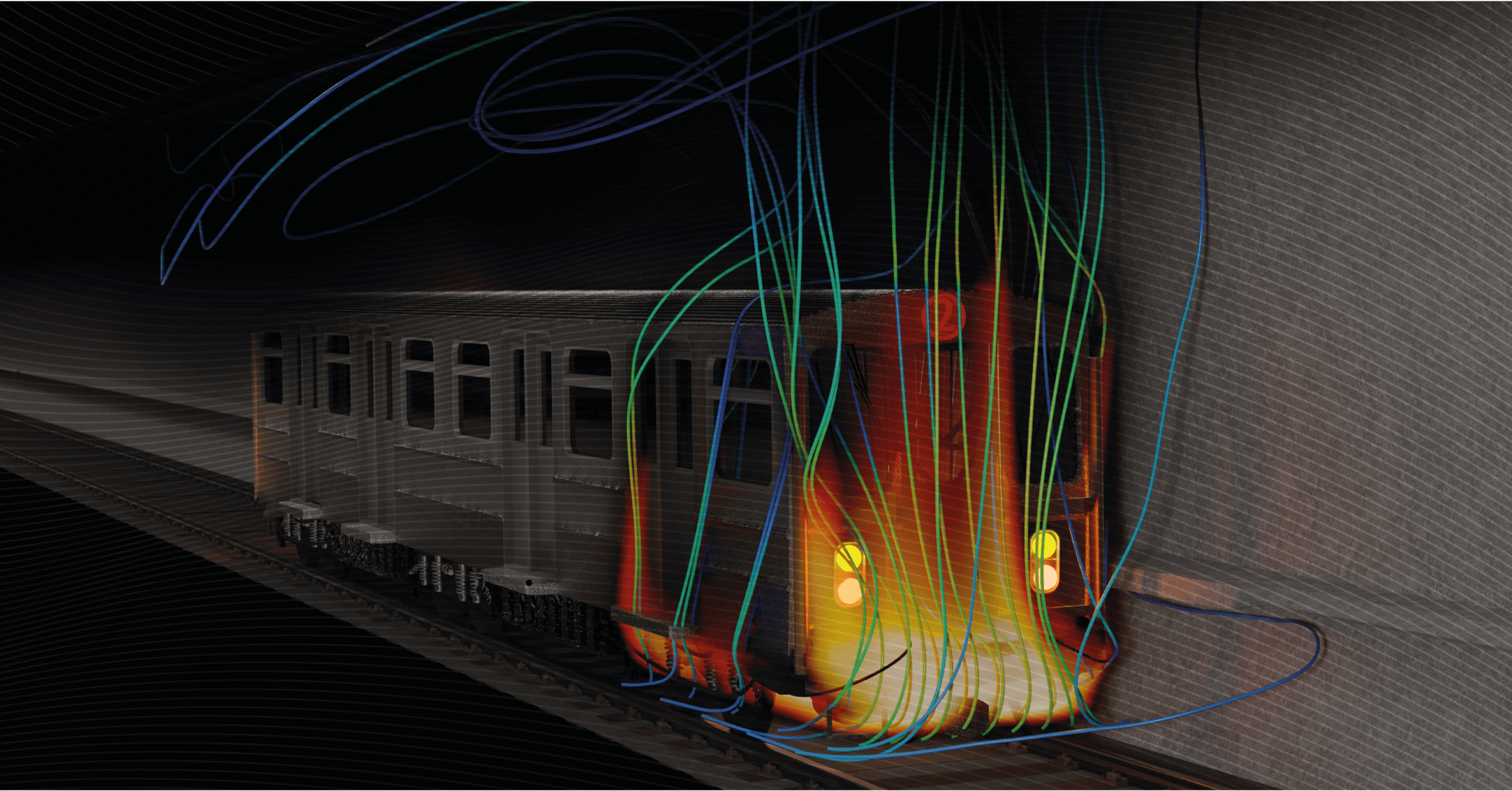

The AENEAS experiment introduced a game-changing solution that revolutionizes smoke control in subway tunnels through advanced HPC-based engineering design. Leveraging high-performance computing resources and cutting-edge CFD simulations, ENGYS, TECNOSISTEM, and CINECA collaborated to develop a unique framework. This approach departed from traditional methods that relied on iterative and approximate techniques with 1D simulation codes. Instead, the AENEAS experiment utilized detailed 3D simulations and time-varying ventilation control, enabling more accurate and effective smoke control strategies.

By employing this innovative approach, the detailed virtual representation of livability and visibility fields during fire incidents, coupled with a time-varying control of ventilation systems, optimized safety and improved the overall effectiveness of emergency response plans. The solution was successfully validated through the design of a real subway line in Southern Italy, demonstrating its practical applicability and real-world impact.

The Business and Societal Impact

The experiment has generated significant benefits for various stakeholders involved in subway tunnel design and construction. TECNOSISTEM, as a result of implementing the solution, experienced estimated average internal cost savings ranging between 7 and 15% in subway line design. This substantial reduction in costs translates into improved competitiveness and profitability for TECNOSISTEM, allowing them to deliver more cost-effective solutions to their clients while maintaining high standards of safety. Additionally, the project has also anticipated an estimated increase in turnover for the company between 4 and 7% over five years. This increase is attributed to the greater effectiveness and induced cost reduction of the civil works.

The experiment has opened up new opportunities for ENGYS as well. By introducing the HPC interface developed for the project into their proprietary software HELYX, ENGYS can offer a unique design framework to SMEs operating in the rail construction and engineering sector. This expansion into new market segments enables ENGYS to provide high-fidelity CFD solutions and contribute to the advancement of engineering design practices in the industry.

Construction companies and communities involved in subway tunnel projects also reap significant benefits from the AENEAS experiment. By downsizing ventilation fans and silencers based on accurate simulations and optimized designs, excavation volumes and related costs can be significantly reduced. This leads to substantial cost reductions ranging from €3 to €9 million for a typical subway line, benefiting both construction companies and the communities they serve. Moreover, the enhanced safety measures resulting from the implementation of the newly developed HPC-based methodology contribute to increased passenger safety during emergencies, reducing risk factors and instilling confidence in underground mass transport systems.

Conclusion

The successful collaboration between ENGYS, TECNOSISTEM, and CINECA in the AENEAS experiment has revolutionized smoke control in subway tunnels. By employing HPC-based engineering design and advanced CFD simulations, they achieved optimal designs, enhanced safety, and significant cost savings. The AENEAS success story sets a new industry standard, offering a unique design framework that ensures safer underground mass transport systems worldwide.

To explore the transformative potential of HPC-based engineering design and learn more about the innovative solutions offered by ENGYS, contact us. Discover how their expertise in advanced technologies can improve safety, efficiency, and cost-effectiveness in smoke control and emergency preparedness for subway tunnels. Join the movement towards safer and more efficient urban transportation infrastructure with ENGYS as your trusted partner.