While the idea of autonomous driving has been around for many decades, recent advances in software, computational power, sensors and mobile communication techniques have accelerated the development and understanding. Already, drive assistance systems, such as lane holding, cruise control and emergency braking have made it into production cars, making a ride in a vehicle more comfortable, safer and have less of an impact on the environment. As the developers and manufactures of such cars climb the rungs of the SAE automation scale, scenarios of vehicles teaming up to ride together will become reality on our motorways. Pilot projects to prove the feasibility and benefits of such convoys or platoons have already been conducted, for example in the SARTRE EU-Project and with the European Truck Platooning Challenge. By having multiple vehicles follow each other at a very short distance (much closer than the safety distance for human drivers) reductions in aerodynamic drag can be achieved that translate into less fuel consumption or extended range for electric vehicles (slipstreaming) and improve overall convoy aerodynamics. On the other hand, having cars run in “dirty” air from a leading vehicle will have effects on the cooling capacity as well as stability and aeroacoustics that developers need to address.

Setup

Using ELEMENTS, our CFD package for vehicle design, ENGYS has conducted a study into the convoy scenario to assess potentials for drag reduction and impacts on cooling capacities. The following parameters were considered

- Number of vehicles

- Distance between vehicles

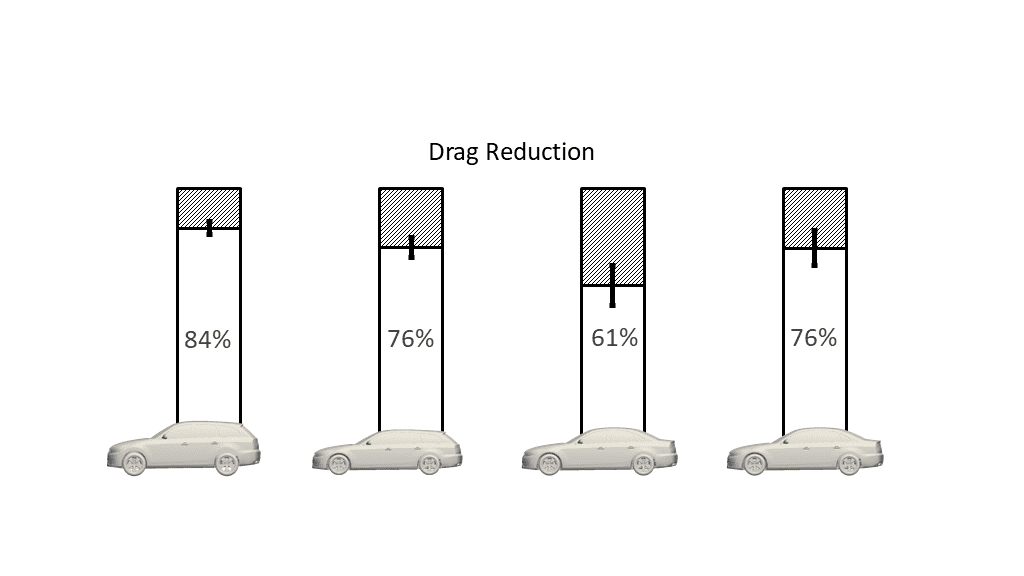

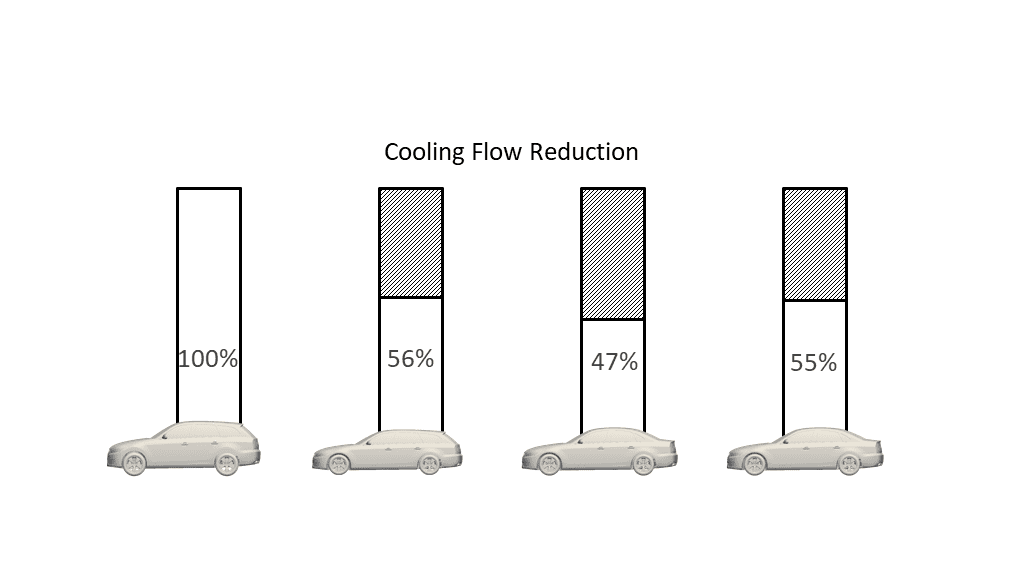

- Type of vehicles

- Order of vehicles (if different types)

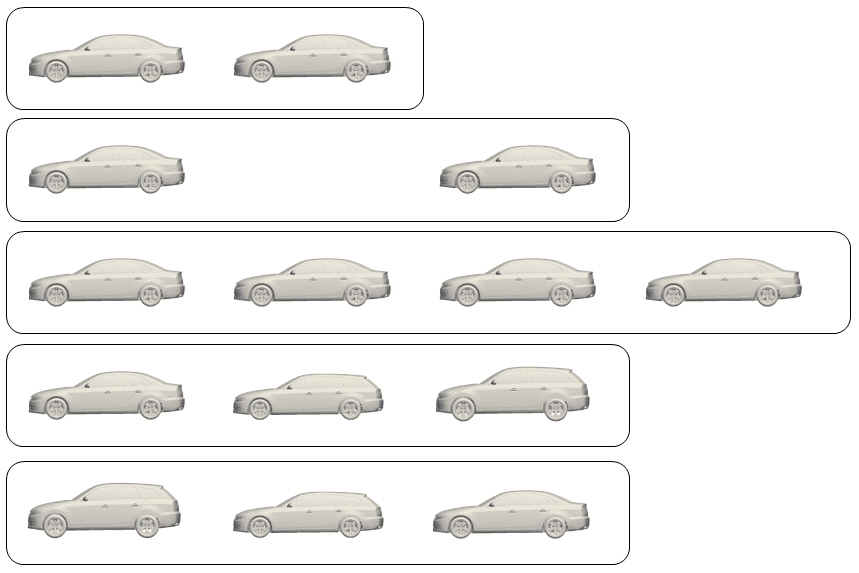

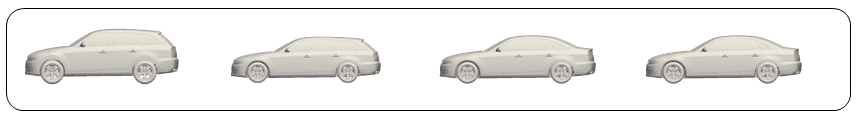

Additionally, a side wind scenario was considered to judge how much benefit is lost when running under such conditions. 3 different DrivAer geometries were used, the Estate, the Notchback (Sedan) and a SUV variant (an Engys derived car, not the more recent AeroSUV). ELEMENTS uses a Detached Eddy Simulation (DES) approach to solve the flow around vehicles. The flow is simulated over a period of time and integral force coefficients are averaged over time. The templated setup for different car shapes allows for fast turn around times, setting up an ELEMENTS simulation for a detailed car takes mere minutes.

Based on that workflow, it was fairly straight forward to extend the model to additional vehicles. The mesh settings are so robust, that a simple copy & paste of those settings for additional cars was sufficient. For longer convoys the virtual wind tunnel (domain size) was extended in x-direction to not have the last car sit too close to the outlet. Flow physics-wise nothing changes between 1 car simulation and multiple car simulations. No solver settings needed to be tweaked. Merely the simulated time to flush the domain and to record the forces needs to be extended for longer convoys.

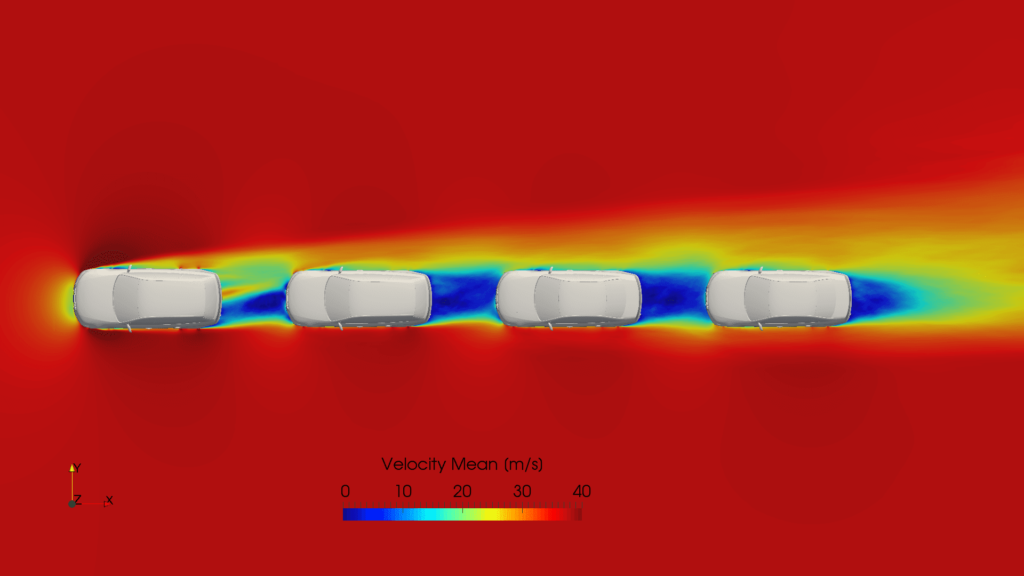

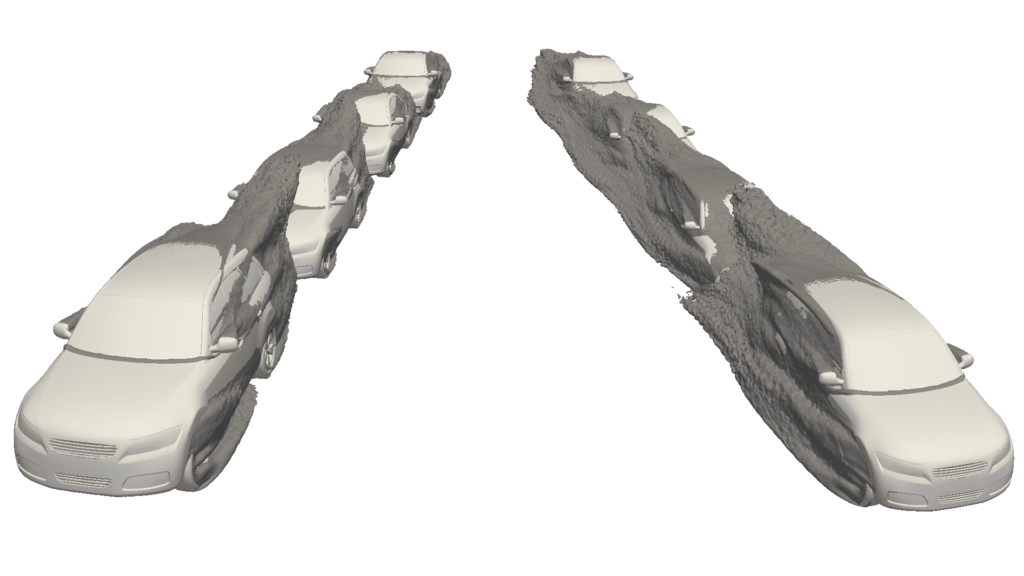

Exemplary for the study results for a 4-vehicle convoy are shown here. Leading the convoy is a SUV variant followed with 2m distance each by an Estate and two Sedans. The conditions include side wind, leading to the overall flow coming in at a 5 deg angle. This will lead to the wake of the vehicles being shifted. Therefore, the mesh refinements were modified to take this into account. Given the close distance, the cars “sit” in each other’s wake refinement boxes, leading to an overall mesh size that is somewhat smaller than 4 times a single car mesh. ELEMENTS created a 280M cell mesh for the whole assembly.

Results

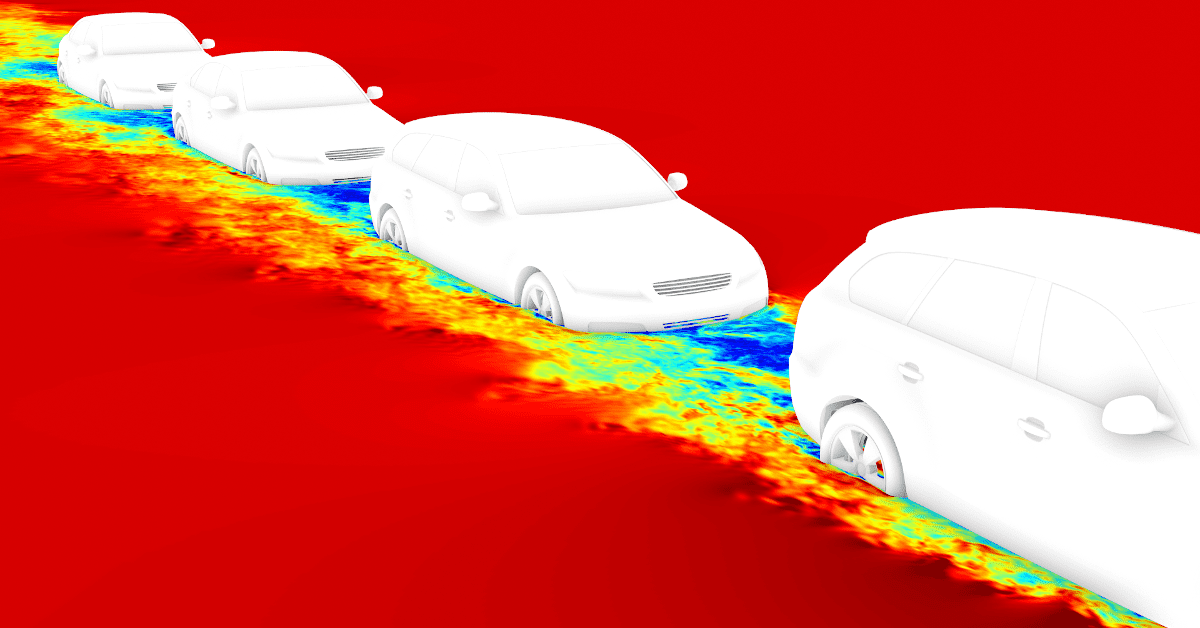

Below a couple of flow field animations highlighting how the cars sit in each other’s wake, resulting in less aerodynamic drag for each one of them.

Animation 1: Velocity contours at wheel axle height.

Animation 2: Isosurfaces of total pressure coefficient.

Time averaged fields for velocity and total pressure coefficient.

The force coefficients were time-averaged and compared to single vehicle simulation to assess the potential benefit. Fluctuations in the recorded drag coefficients can be assessed for example by looking at the standard deviation. The elevated levels of fluctuations for the trailing vehicles can potentially point to issues with buffeting. Impacts on aeroacoustics characteristics need of course a more detailed simulation. The whole convoy reduces the drag by ~25%. This is under side wind conditions. With no wind the benefits are larger.

Additionally, the cooling flow is also compared to single vehicles in clean air. Unsurprisingly, the cooling flow through the front is significantly reduced for the trailing cars. This must be taken into account when desiging convoy driving concepts.

Conclusions

When designing future systems for autonomous vehicles to drive in a convoy, one scenario could be that a (distributed) control software automatically assigns an optimal position to vehicles in a convoy and adapts the configuration as vehicles enter and leave the formation. Without endlessly reshuffling the cars in a trial and error approach, no doubt resulting in considerable irritation of the passengers, that can only be achieved if the software has prior “knowledge” of the optimal convoy setup for a given number and type of vehicles. Machine learning based systems need training data and given the size of the parameter space (number of vehicles, type of vehicles, distance between vehicles, order of different types of vehicles) only simulations can reasonably be an option to populate that database.

We could prove here that ELEMENTS not only can handle this kind of multiple vehicle scenarios with very little additional user effort, but also that the open source nature of ELEMENTS means that the huge number of different configurations can be worked through in a very cost-efficient manner without sacrificing accuracy.

In scenarios and flow regimes where steady state simulations usually provide sufficient accuracy, the ELEMENTS-Coupled solver technology can offer significant speed up.