The ambition of every race team is simple: develop the fastest car possible within the regulations. Achieving this however is a monumental challenge, particularly when those regulations continue to squeeze budgets, resources and testing time.

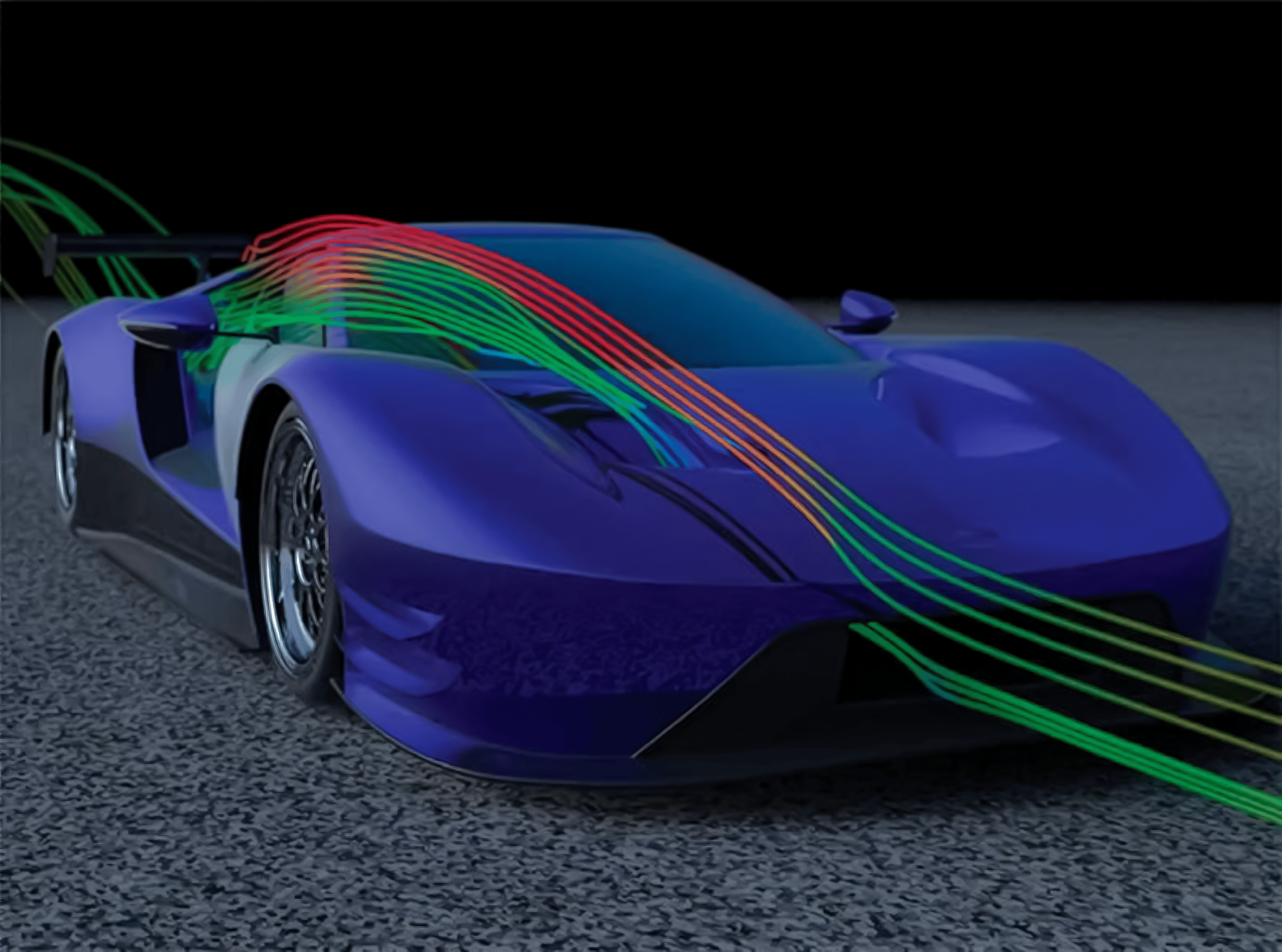

So how do teams continue to improve the aerodynamic performance of their race cars to stay competitive, whilst abiding by these tight testing restrictions? The answer lies in utilising powerful Computational Fluid Dynamics (CFD) simulation tools such as HELYX that are time, compute and cost efficient.

The Evolution of Racing Regulations

Historically, testing was unrestricted in motorsport, with the only limitation being how much teams could afford to spend. Consequently, by the mid 2000s in championships such as Formula 1, teams were running extensive test programmes. These involved up to 80 days of track testing, three cars and a dedicated test team, alongside 24/7 wind tunnel testing across multiple facilities – escalating total budgets to over $400 million a year [1].

In an attempt to control costs, the FIA introduced the first testing restrictions in 2008, limiting track testing to 30,000km a year. This was closely followed by the Aerodynamic Testing Restrictions (ATR) in 2009 which regulated test time in wind tunnels, scale models to 60% and maximum wind speed to 50m/s (180kph) [1]. While the number of teraflops for CFD simulations was also controlled.

Over the years, the FIA continued to tighten these rules together with introducing an overall cost cap of $135 million [2]. Today, Formula 1 teams are only permitted to three days of track testing and are now heavily limited on the amount of wind tunnel and CFD testing they can complete. They are also constrained on the number, occupancy hours and operation hours of power unit bench testing.

‘Race teams are experts at maximising productivity of the constraints they are put under by the regulations,’ highlights Angus Lock, General Manager at ENGYS. ‘Teams in some championships are limited by budgets, while others must comply with strict testing regulations. In both cases, teams need to extract every core hour from their available CFD resource for aerodynamic development and ensure that they are not only getting fast results, but accurate results as well.’

The Secrets To HELYX’s CFD Solver Performance

The key to delivering fast results whilst maximising the number of runs within a limited resource and cost budget lies in efficiency. This is the fundamental principle that has driven every development of HELYX and ELEMENTS software, and has led to the implementation of new meshing techniques, a block-coupled solver, single precision and an open-source infrastructure. All of which powers ENGYS software to accelerate runtimes, utilise every core and run parallel simulations for a fraction of the cost of conventional CFD platforms.

Faster Solver Speeds With HELYX-Coupled

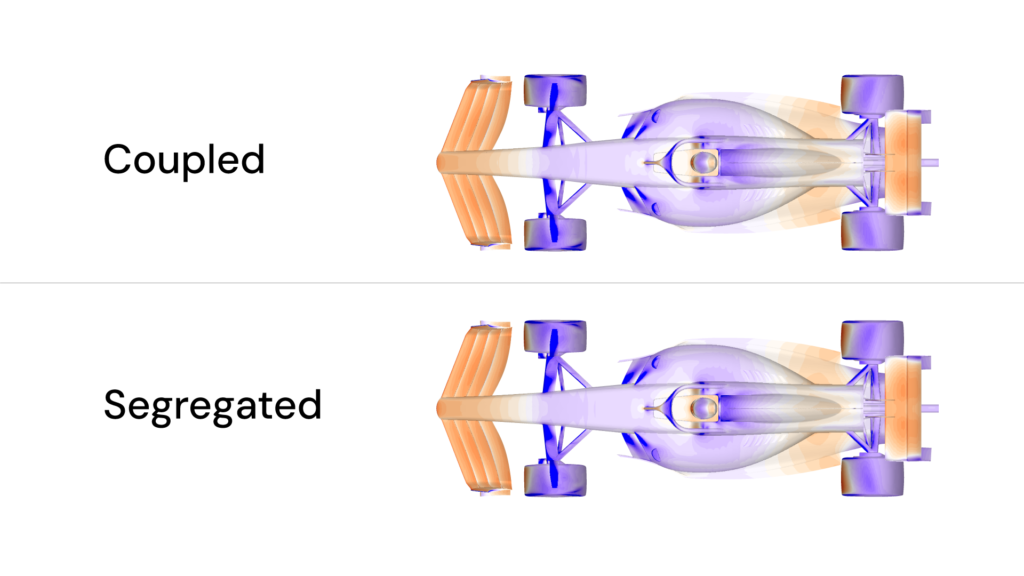

ENGYS’s block-coupled solver, HELYX-Coupled, is at least twice as fast and, in some cases, up to ten times faster than traditional segregated solvers. This is achieved by maximising throughput via a local time stepping approach using Courant (CFL) scaling. Therefore, simulations are completed in half the time, so teams can run more design iterations for the same compute budget, helping them to innovate faster and overall make more informed aerodynamic decisions.

Accelerated Runtimes For Transient Simulations

Some championship regulations limit the number of geometries teams can test in CFD, which means studies such as Fluid-Structure Interaction (FSI) are not possible as the rules consider each deformation of a structure as a new geometry. This combined with the need to resolve correlation issues between CFD, the wind tunnel and the track is encouraging teams to complete more transient simulations instead of just steady-state.

‘For RANS and external aerodynamic cases, HELYX typically achieves around 40% shorter runtimes for transient simulations with our segregated solver,’ reveals Lock. ‘The main reason for this is our approach minimises the number of pressure-correction iterations when compared to traditional segregated solvers.’

Single Precision Scalability And Performance Gains

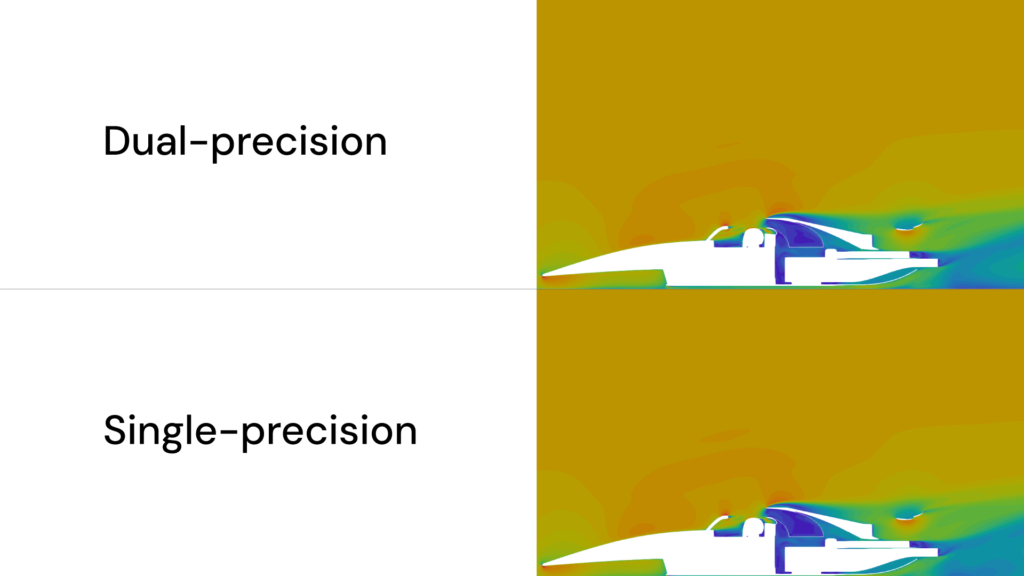

One of the most recent improvements in CFD performance has been the switch from double precision to single precision. Currently, most CFD tools still run double precision (FP64) which stores 64 bit floating point numbers with around 15 to 16 digits of precision. While single precision (FP32) uses 32 bit numbers with around 7 to 8 digits of precision. This effectively halves the storage and memory bandwidth per operation, achieving faster calculations.

‘When we first talked about implementing single precision, no one thought it was possible, but the ENGYS developers have done a great job at making it work,’ explains Lock. ‘So now single precision is available in HELYX for both the HELYX-Coupled and segregated solvers. But for simulations where higher precision is required, users can switch to double precision.’

‘Single precision also scales more effectively, which has become particularly important as teams move their CFD simulations on to the cloud,’ continues Lock. ‘Ideally, you want every core executing useful work, but the high memory bandwidth of double precision can cause bottlenecks. Whereas, single precision essentially doubles the usable memory bandwidth per core, allowing more jobs to be completed in parallel.’

Accurate Meshing Techniques

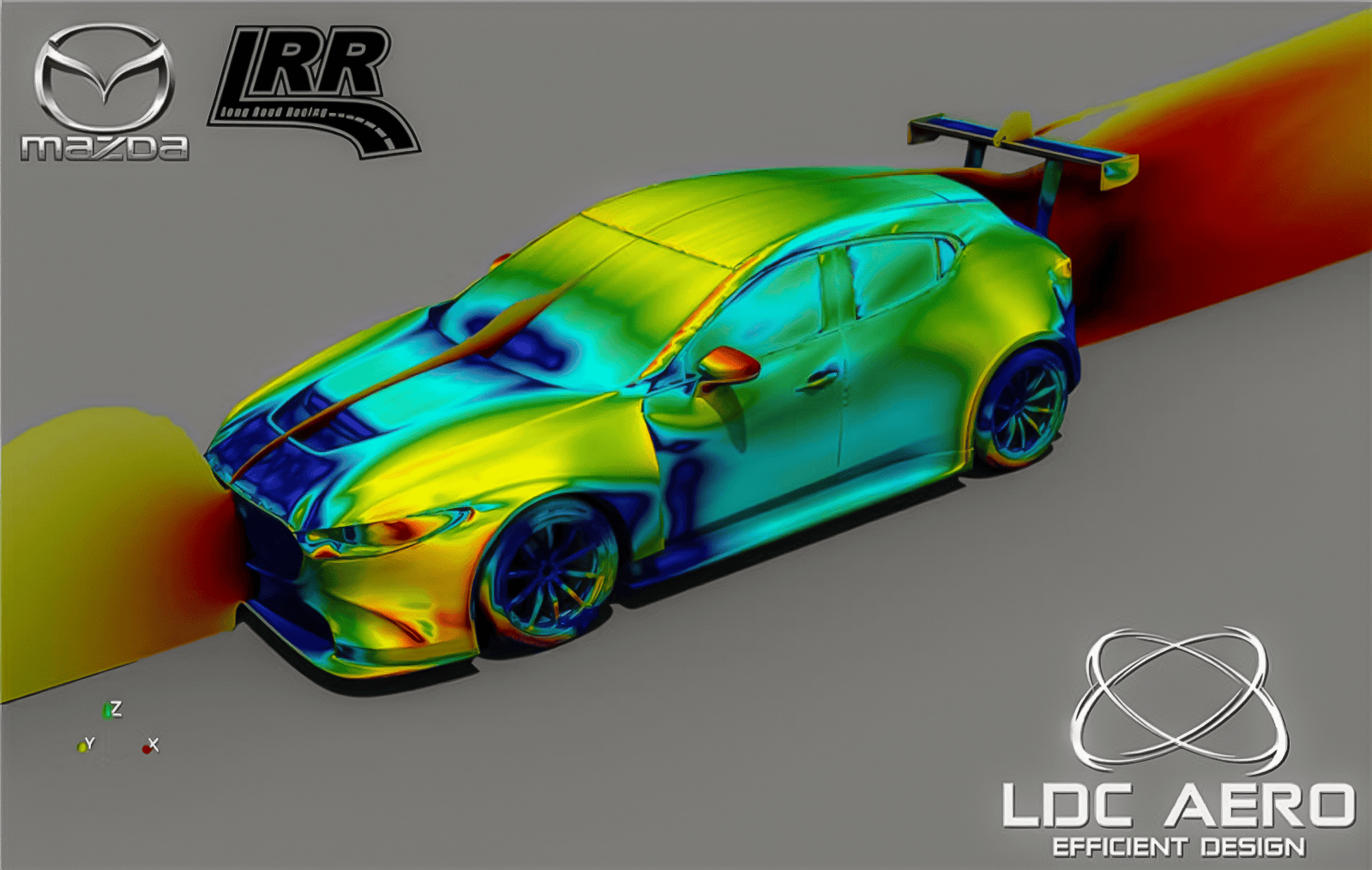

Mesh quality is yet another factor that contributes to faster run times and more accurate results as the higher the mesh quality, the lower the numerical errors and instabilities. ENGYS’s helyxHexMesh utilises an extrude mesh algorithm that guarantees full boundary layer coverage and low y+ meshing. It uses hex dominant elements in the far field for efficiency and polyhedral elements close to walls. Other codes typically use pyramid chains and wedge transitions which can reduce solver robustness on challenging surfaces.

The Cost Efficiency of Open-Source

The tight turnaround times in motorsport mean that teams need large clusters, capable of running multiple jobs simultaneously. However, the traditional per core or per job charging structures of conventional CFD software packages can escalate costs quickly for race teams.

‘As our software is open-source, it is extremely competitive in terms of costs and scalability,’ says Lock. ‘Teams have the freedom to run simulations concurrently on an unlimited number of cores, without having to pay for additional licenses. This is ideal for teams who have to operate within restricted budgets and cost caps.’

Adapting To Race Team Requirements

The development of HELYX has revolved around the motorsport market and therefore every release is tailored to the aerodynamic demands of race teams. ‘One of the biggest differences between ENGYS and other CFD platforms is how responsive we are to requests,’ says Lock. ‘For example, if a team wants us to implement a particular turbulence model, we will execute this in a matter of days, even with the complex workflows used in high level motorsport. Whereas with larger CFD organisations, you could wait months for your request to be implemented.’

‘We offer race teams a CFD tool that is accurate, arguably more accurate, than conventional CFD software’s, but delivers results significantly faster,’ concludes Lock. ‘We continuously improve robustness and reliability and are always adapting the code to suit the latest developments in high level motorsport. Teams appreciate that we listen to them, and that’s why our presence in motorsport continues to grow, with 7 out of 10 Formula 1 teams now using HELYX.’

References

[1] G.H., 2023. Beyond the Limits. Racecar Engineering Magazine V33N9.

[2] L.L., 2025. F1 cost cap: What is the F1 cost cap? How much money can F1 teams spend? [Online]. Crash.net.