Amongst the most significant changes that the 2022 FIA regulations brought to Formula 1 are those directly related to the aerodynamic design of the car. With attention focused on the revolutionary 3D-contoured underfloor, the teams now heavily rely on its efficient design to produce the majority of the car’s total downforce. This new tunnel-style underfloor, however, has led to the return of the so-called “porpoising” phenomenon which has been observed since the late 70s when the first ground effect cars were introduced by F1 constructors. Simply put, “porpoising” is a periodic aerodynamic phenomenon during which the car bounces away from the ground when it’s underfloor stalls and then it is pulled down again once the aerodynamic performance of the underfloor is recovered. Long discussions have been raised over “porpoising”, the severity of which has been affecting drivers and cars especially during the early season.

Using CFD to simulate the “Porpoising”

To simulate such a complex phenomenon using Computational Fluid Dynamics (CFD) and dynamic mesh deformation techniques is not only technically challenging but could also consume a significant amount of a teams’ available CFD resource allocation units on a single simulation, thus significantly impacting resource availability for conventional design optimization. To create a simulation methodology that can give further insight into the car’s aerodynamic performance during “porpoising” while maintaining a viable computational cost, ENGYS employed its Generalized Internal Boundary (GIB) technology. This technology makes it possible to simulate complex body motions by snapping the computational grid’s internal faces to the body which is introduced as an interface inside the mesh. This removes the need for cell quality remediation and re-meshing to maintain a viable grid, which would be the case if a dynamic mesh deformation plus re-meshing approach was used, resulting in a much less computationally expensive alternative without compromising the accuracy of the solution. In addition, the new approach uses a single representation of the vehicle, which is beneficial from the perspective of resource allocation units in F1.

Approach description – Initial Consideration

The foundation upon which this methodology is built is the assumption that the ground is moving relative to the car rather than the opposite (which is the actual case). The reason behind this initial consideration is the fact that modelling the ground as GIB and snapping the computational grid on a flat surface is much less challenging for the solver than snapping on the car’s complex surface, which means that turnaround times are reduced. For the purposes of our demonstration the motion of the ground is modelled as a prescribed, constant-frequency oscillating motion along the vertical axis.

Simulation Setup

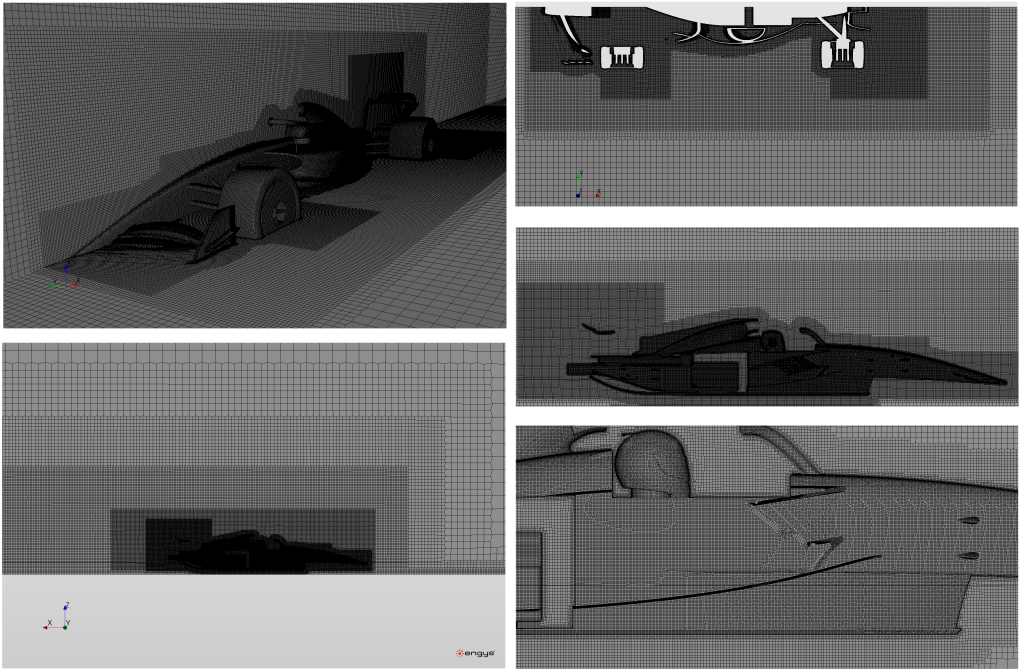

Starting from the mesh setup, a rather coarse grid consisting of approx. 25M cells is considered sufficient to be used for demonstration purposes. To further minimize the cost of the simulation, a half-car analysis is employed. Of major importance for the success of that methodology is the maintenance of a uniform cell size under the car to ensure better snapping of the GIB.

A segregated flow solver along with a transient RANS approach is used for the analysis. The kw-SST model is employed for the turbulence closure. A converged steady state solution is used to initialize the flow field, with a constant integration timestep of dt=0.005s based on the reference velocity, the mesh characteristics and the timescale of the “porpoising” phenomenon.

Results

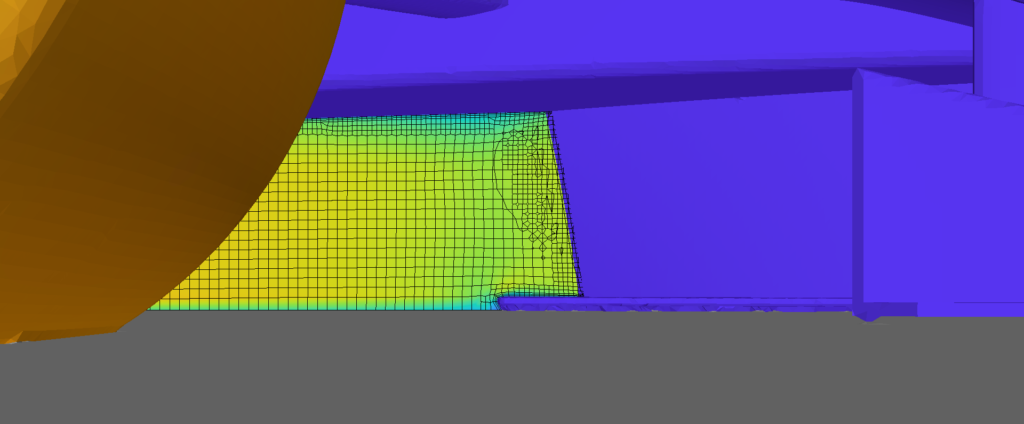

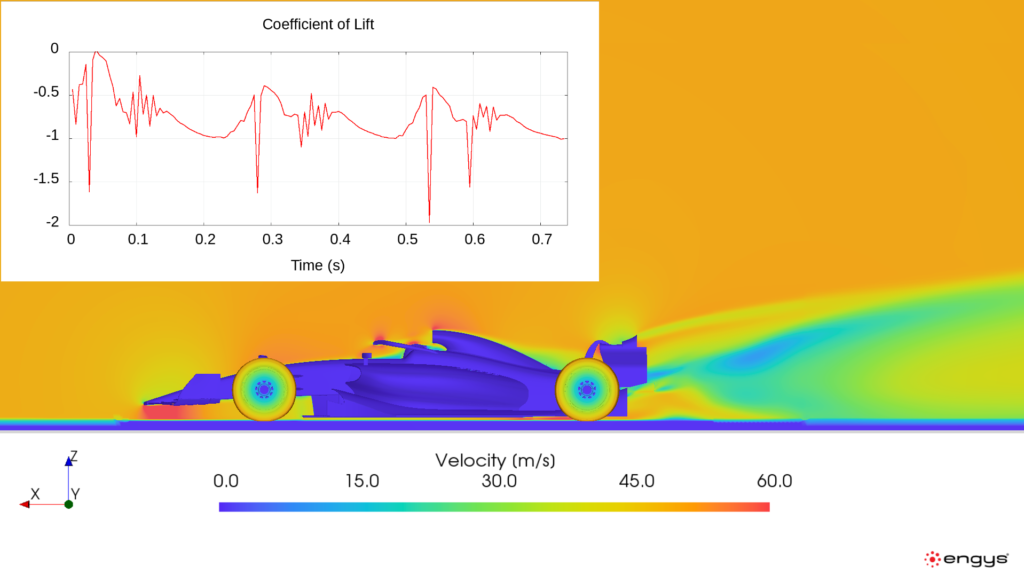

The animation above demonstrates how the velocity around the car is affected during “porpoising”. The effects are particularly distinct at the diffuser where the flow is completely cut off when the car hits the ground and then it gradually recovers as the car moves away from it. The animation also demonstrates how the mesh snaps to the moving GIB interface underlining the GIB’s capability to effectivelly handle boundary intersections.

The computational cost for simulating 0.5s of the phenomenon was approximately 7.5 hours on a 128 core computer.

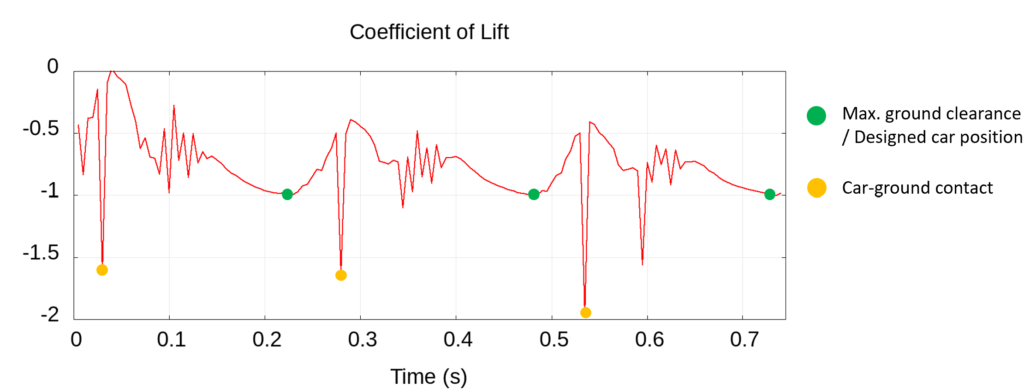

The evolution of the lift coefficient over time is presented in Figures 3 and 4. What’s interesting about the results is the suggested hysteresis in the downforce recovery as the car moves away from the ground. The large spikes that occur when the GIB intersects the skid-plate are computational artifacts from the lack of force integration in ground penetrating surfaces and have no direct physical meaning. The lower amplitude spikes after ground contact appear to be related to GIB snapping difficulties in mesh regions with varying refinement levels (including prism layers), which underlines the importance of maintaining an overall uniform cell size under car. We intend to address both these issues as part of future development efforts.

Conclusions

The aim of this project was to provide teams with a viable way to simulate “porpoising” and gain further insight with respect to the car’s overall aerodynamic performance during such events. Despite its limitations, the proposed methodology has successfully made an approximate assessment possible, giving an overview of how the aerodynamic performance of each individual component changes with ground proximity and how the overall balance and stability of the car are affected as a result.